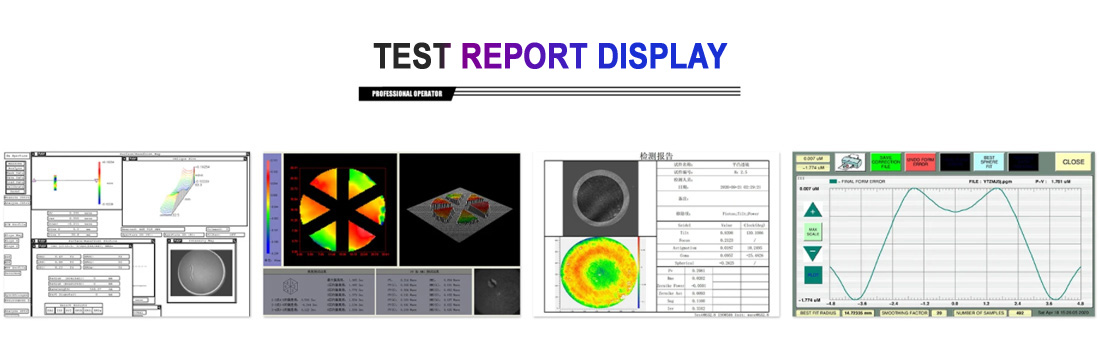

ISO9001 Certified Professional Manufacturer & Supplier of Optics

+86-0431-87911611 admin@ytoptics.com

Contact us

-

Email: admin@ytoptics.com

Email: admin@ytoptics.com

-

Tel:86-0431-87911611

Tel:86-0431-87911611

-

Add: 2# Automotive Innovation

Add: 2# Automotive Innovation

Jilin Province, China

Basics of Optical Spherical Lens Processing

Optical parts processing, divided into hot processing, cold processing and special processing, hot processing is currently used in the preparation of optical parts blanks; cold processing is a bulk abrasive or solid abrasive sawing, rough grinding, fine grinding, polishing and centring edge grinding. Special processing only changes the performance of the polished surface, without changing the shape and size of the optical parts, which includes coating, scaling, photographing and gluing. The main task of each process of cold processing is: milling process: to remove the uneven surface of the lens bubbles and impurities, play a role in shaping; fine grinding process: is to make the parts processed to the specified size and requirements, the milling out of the lens to eliminate the destructive layer of the large only fixed R-value, ready to be polished; polishing process: is to make the parts surface is bright and reach the required optical precision; centring process: is relative to the optical axis Centring process: to process the outer circle of the lens relative to the optical axis, to grind the outer diameter of the lens to the specified diameter; Coating process: to coat the surface of the lens with a film layer to increase the transparency, reflection, etc.; Gluing process: to glue different optical parts together to make them reach the optical axis coincide with each other or to turn in a certain direction; Coating process: to coat a layer of black ink on the hairy side of the lens to achieve the purpose of light elimination;

PREV : AR coating & IR coating NEXT : Semiconductor laser lenses

TALK TO US 86-0431-87911611

86-0431-87911611

Call us now!

86-0431-87911611

86-0431-87911611Call us now!

ONLINE CHAT

2433808388

2433808388